Rack-mounted equipment in server cabinets are expensive assets in IT infrastructure. It is imperative to ensure that the rack and its equipment are performing fault-free, and as efficient as possible.

It is critical to monitor the performance of your rack, especially the temperature, humidity, leakage, power, and airflow. When faults occur, to ensure the uptime of equipment, the monitoring system can perform actions automatically (e.g. activate additional fans, sound an alarm, or send alarm notification). With an embedded interface and support for SNMP software, it is easy to evaluate environmental data in a straightforward way to prevent the failure of equipment.

Vutlan’s rack monitoring solutions help data center and facilities managers:

Setting Up Alert Thresholds & Notification Alerts: Send Email, SMS, Syslog, Event log, SNMP Trap, SNMP Get, sound and light an alarm beacon or a strobe light.

Maintain Relative Humidity Levels: Maintain proper humidity levels, avoid hardware corrosion when relative humidity is too high, and electrostatic discharge (ESD) problems when humidity is too low. Recommended ambient relative humidity levels for optimal performance and reliability are between 45% and 55%.

Detect Water Leaks: Detect if there is a water leak from external sources or from pipes in a water-cooled rack.

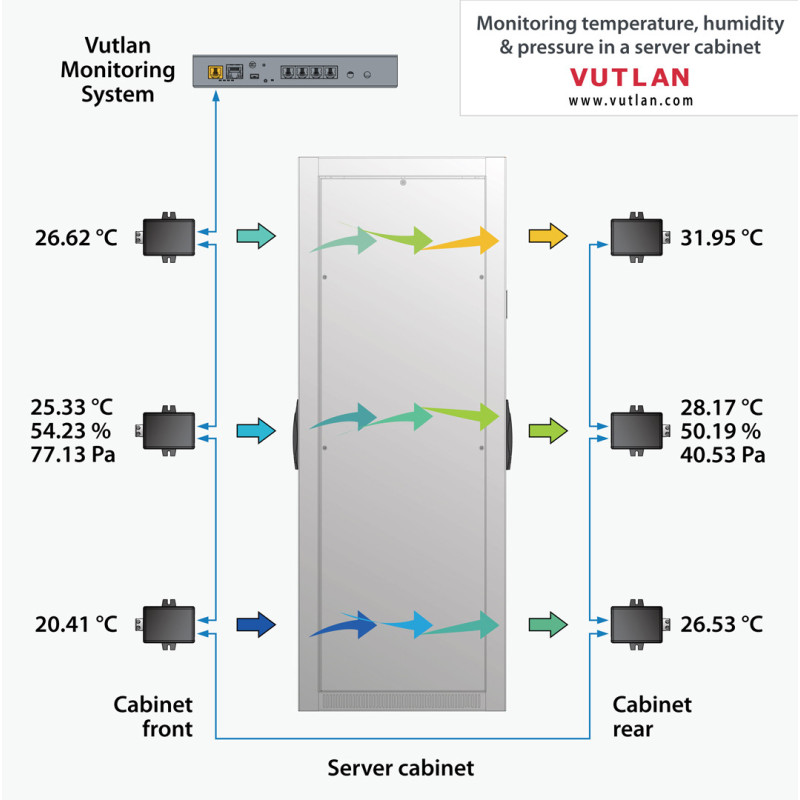

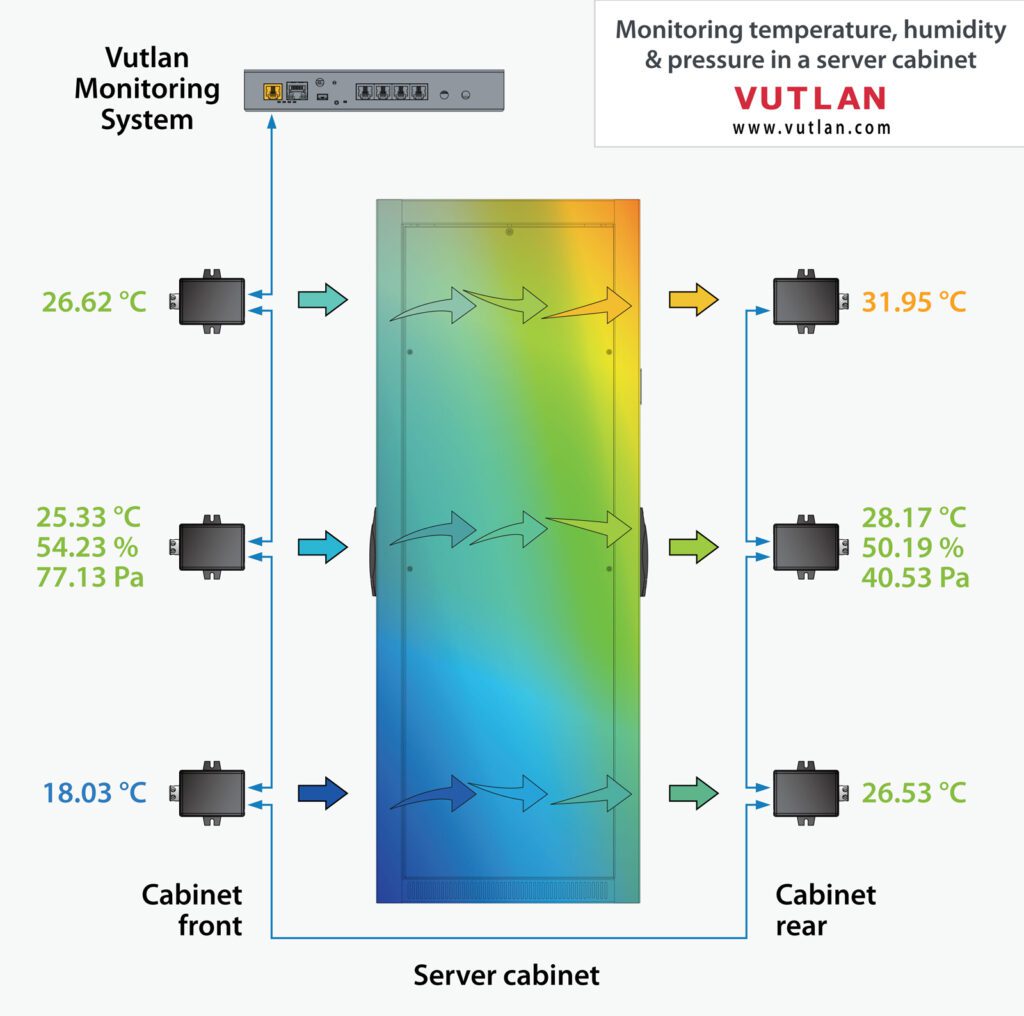

Monitor & Manage Airflow: Monitor flow rates of cooling and hot air return to ensure cooling and containment systems are functioning optimally.

Maintain Optimal Temperature: Measuring the temperature at multiple height levels of the rack can give an early indication of a potential temperature problem. Vutlan monitoring units will provide early warnings and notify staff for temperature issues. This information can help the staff optimize the cooling system by safely raising the ambient temperatures. Recommended optimal temperature range for system reliability is 68° to 75°F (20° to 24°C).

Track Security Threats (Sabotage or Damage): Monitor and administer who has access to your racks. Allow access remotely for I-Touch or Proximity readers. Get notified if the rack has been hit using our vibration sensor VT540. Or stream JPEG stream from USB camera if the back door has been opened.

Monitor and Report: Vutlan monitoring units are fully compatible with all major SNMP network management systems (NMS software) like Open NMS, Nagios, HP Network Node Manager, IBM Tivoli and so on. See the compatibility list.

Manage Power: Measure voltage or current using AC/DC meters. Switch ON/OFF outlets using Vutlan’s switched PDUs and monitoring units with PDUs.

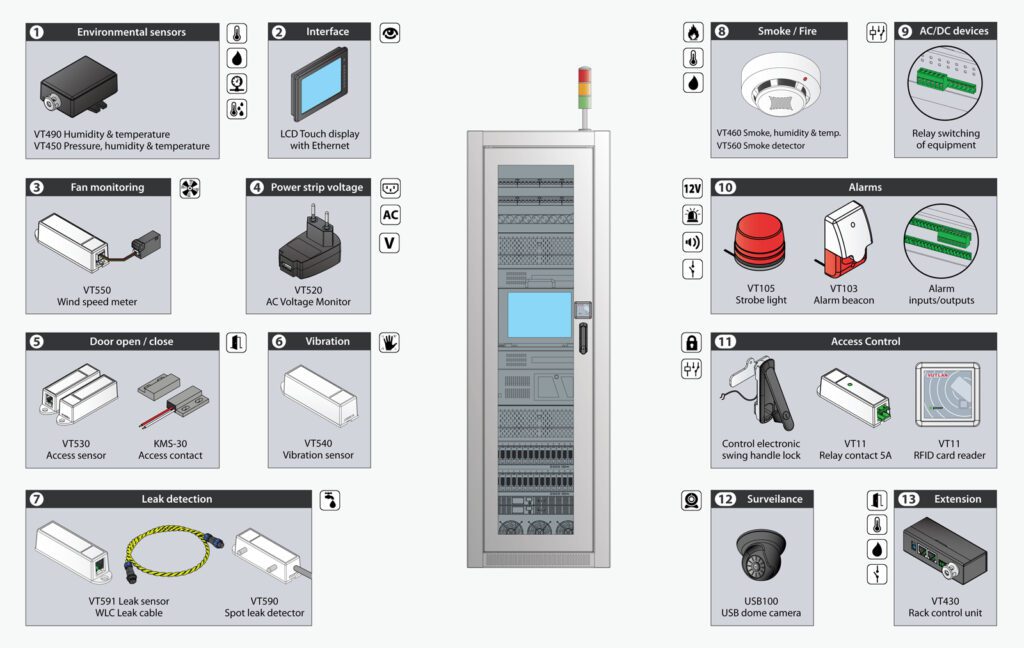

Server cabinet monitoring components

1. Monitor

Temperature, humidity, pressure

VT490 & VT450 are high-quality sensors with reliable price. Both sensors are CAN chainable.

- Can be connected in a chain

- Multiple sensors in one device

- Affordable price

- Easy to connect and configure

2. Display a dashboard

with sensor data

Any display with a browser support can access Vutlan Web Interface.

- Can be mounted near the rack

- Can be shown in operator room

3. Monitor

Airflow speed

VT550 airflow speed meter is used for installation on Air conditioners, fans, and other places to measure wind (airflow) velocity. Sensor monitors airflow 0 – 3 m/s. The sensor is an analog plug-and-play and it is connected to any analog port of any Vutlan monitoring system.

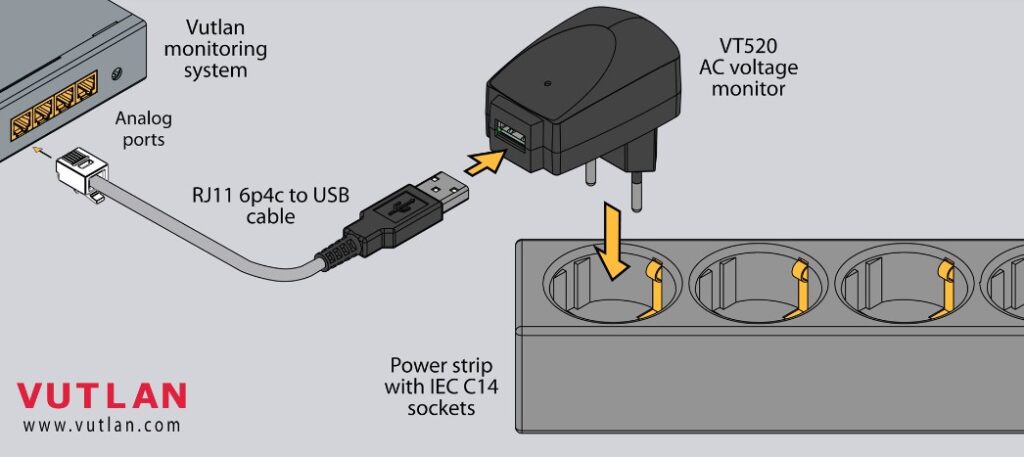

4. Monitor

AC voltage

The sensor measures AC voltage in the range 0-246 V. An analog plug-and-play sensor.

Two models: VT520 & VT520DIN

For power sockets IEC C14

Perfect for monitoring voltage in power strips

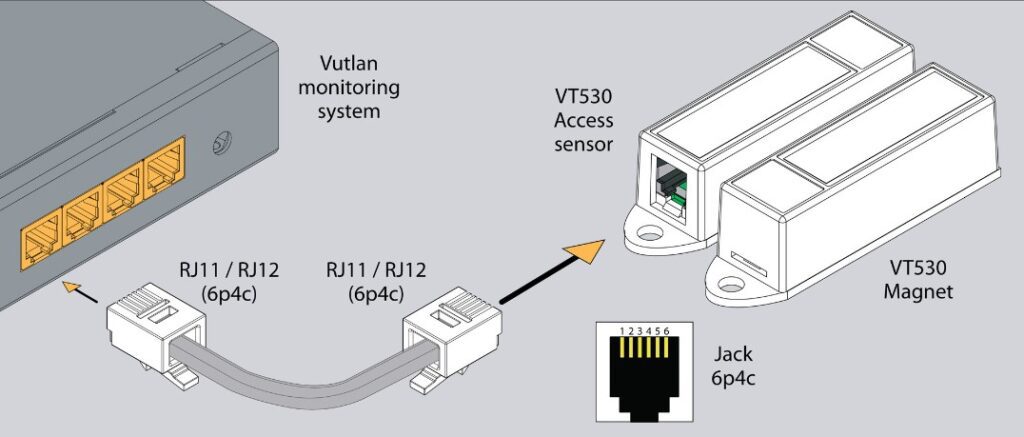

5. Monitor

door access

VT530 and KMS-30 are perfect for door access monitoring of a server cabinet rack. Monitors the status of the door: opened, closed. The sensors consists of two parts: a magnet and a sensor.

Two models: VT520 & VT520DIN

For power sockets IEC C14

Perfect for monitoring voltage in power strips

6. Monitor

vibration

Detects vibration. For installation on walls, windows, etc., the sensor controls vibration. For example, detects the breaking of the window by an intruder if installed on the window glass.

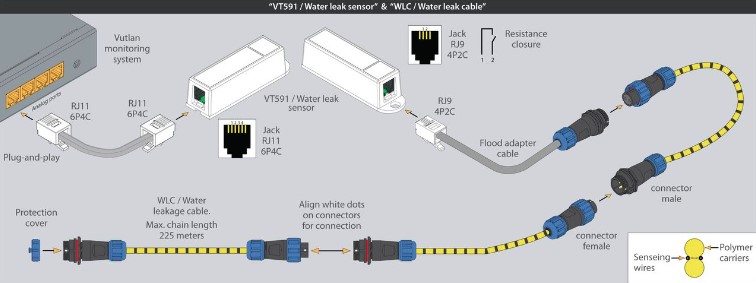

7. Monitor

water leakage

The whole area can be effectively monitored by placing the leaked cable near or along with possible flood sources. “VT591 requires “WLC / Water leakage cable”.

- The sensor reacts to just a few drops of liquid on WLC cable.

- Can detect the emergence of moisture.

- The cable is flexible and easy to install.

- VT591 is an analog plug-and-play sensor.

- After the flooding, the leak detection cable can be dried and reused.

- The sensor does not produce false alarm signals when bent or twisted.

- Detectable liquids include clean, polluted, and distilled water; acids; alkalis; alcohols, and other electrically conductive liquids.

- Different length of leak detection cavles availabe for order.

- Possibility to extend the WLC leakage cables by connecting them to each other.

VT591 leak sensor + WLC cable leak sensor

- An analog sensors for monitoring the whole area of the floor, perimeter, or layed under the pipe routes.

- Detectable liquids include clean, polluted, and distilled water; acids; alkalis; alcohols, and other electrically conductive liquids.

VT593 spot leak sensor

An analog sensor for detecting water leakage at a single point.

VT594 BMS leak sensor

Used in BMS systems for monitoring leakage for whole floor areas, perimeter and along the pipe routes.

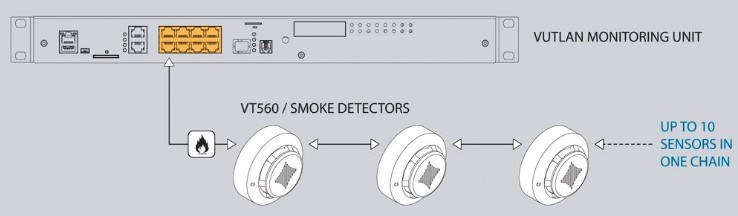

8. Monitor

smoke & fire

These sensors monitor the occurrence of smoke inside the building. Both sensors allow a daisy chain connection of sensors.

VT460 smoke, humidity & temperature sensor

A CAN bus sensor. Can be chained with other CAN sensors and CAN devices/extensions. A value for each sensor can be monitored and used to event automation separately.

VT560 smoke sensor

This is an analog sensor. Multiple VT460 sensors can be chained in one chain on a single analog port (all sensors are shown one one single sensor in Vutlan Web Interface).

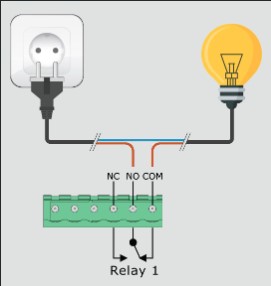

9. NC NO COM relay switching

These systems can connect up to x2 loads managed by built-in relays. Built-in relays have independent separate entrances and exits. The appliances use latching relays, when the power on the appliance switches on/off, relays remain in the command position! Relay switching can be done via automated events.

10. Dry contacts & 12V DC alarms swithing

12V DC relay switching

These systems can connect up to x2 loads managed by built-in relays. Built-in relays have independent separate entrances and exits. The appliances use latching relays, when the power on the appliance switches on/off, relays remain in the command position! Relay switching can be done via automated events.

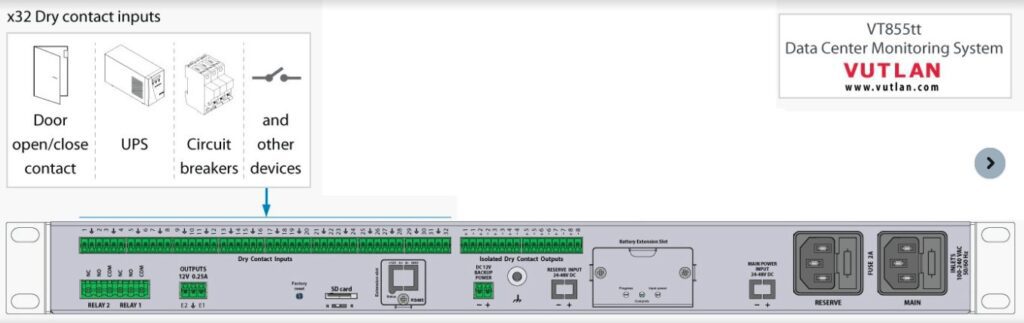

Dry contact inputs (receive signals)

Most Vutlan monitoring systems have dry contact input terminals. It allows the system to receive alarm and alert signals.

You can connect the contact door sensor, window sensor, UPS, alarm system, diesel generators, circuit breakers, control panels, and other industrial equipment.

You can send a signal to a UPS, diesel generator, circuit breaker, control panel, alarm system and other industrial equipment.

Dry contact outputs (send voltage signals)

Some Vutlan monitoring systems have dry contact output terminals. It allows the system to send alarm and alert signals.

You can send a signal to a UPS, diesel generator, circuit breaker, control panel, alarm system and other industrial equipment.